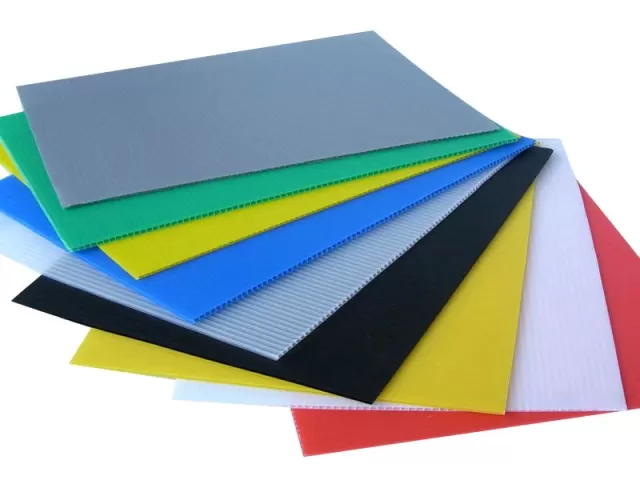

PP hollow plate is polypropylene raw material mixed with polyethylene raw material through the hollow plate production line extrusion molding, the cross-section of the plate is lattice shape, so it is also called lattice hollow plate. It does not produce dust during use, and has a long service life, which is more than 4-10 times the life of corrugated cardboard, and can be recycled. It has the trend of gradually replacing paper corrugated board, mainly reflected in product packaging.The Hollow Plastic Sheets have the following advantages:

1.Hollow plates are mostly made of PP plastic material through high temperature extrusion molding, which has excellent mechanical properties, has strong impact resistance, high compressive strength characteristics, compared with other plates to achieve the same effect, to use more materials, while heavier weight, and hollow plates can achieve fewer consumables, low cost, light weight advantages.

2.Because the interior of the hollow plate is a hollow structure, and the heat transfer and sound transmission are required media, the effect of heat transfer and sound transmission is worse than that of the solid plate, but on the contrary, this can bring better heat and sound insulation effects for the hollow plate.

3.Because the hollow board can bring different performance through modification, mixing, surface spraying and other methods, it can make the hollow board have the corresponding anti-static, flame retardant and other additional performance.

4.Due to the environmental characteristics of raw materials, the entire process of hollow plate from production, processing, waste treatment will not cause pollution to the environment, but also can be recycled into other plastic products to use, has a very superior environmental performance.

5.the choice of color is also very rich, and the suitable hollow board products can be customized according to customer needs.