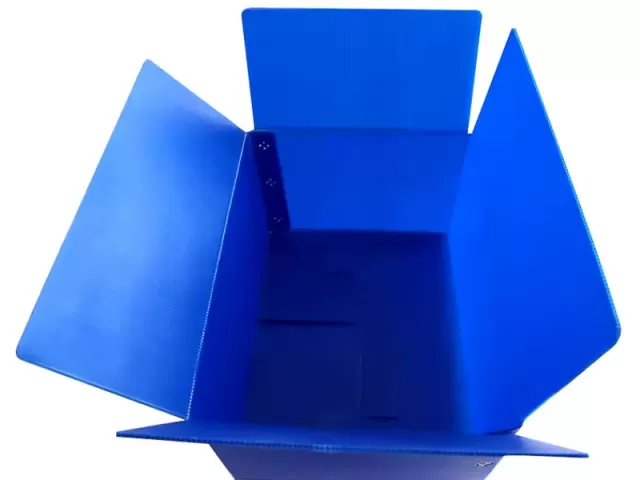

Plastic corrugated box referred to as hollow board box or hollow board turnover box, it is composed of hollow board and related parts and accessories, mainly used for parts turnover and transportation, in the process of logistics effectively protect items from injury and collision.

1.Plastic corrugated box is non-toxic, tasteless, moisture-proof, corrosion-resistant, light weight, gorgeous appearance and rich color, tough, pressure resistance, smooth appearance, oil resistance, defective products can be repaired and maintained, and waste products can be recycled.

2.The size of the plastic corrugated box is made according to customer requirements. The side strips can be made of aluminum alloy, PP and PVC materials, plus round handles with holes, PP rotation Angle, PE plastic card bags can be affixed on both sides, and the box surface can be screen printed with company LOGO and number; Easy to fold and save shipping space for recycling and factory warehouse space when products are not packed.

3.Foldable, does not take up space, convenient for sea export. Waterproof, high recycling times, recyclable. Light weight, large carrying capacity, easy to move.

4.Plastic corrugated box from the appearance is a great advantage, neat and smooth, easy to be colored, not only improve the quality of the box, but also can clearly know the situation of the goods, this color and pattern will not fade because of the passage of time.

5.Plastic corrugated box has the properties of anti-stretching, anti-tearing, anti-folding, anti-aging and light weight, so the Polypropylene Hollow Plastic Box made of hollow plate also has this feature, which can buffer the various goods in the box and withstand the impact, and can also better protect the load.