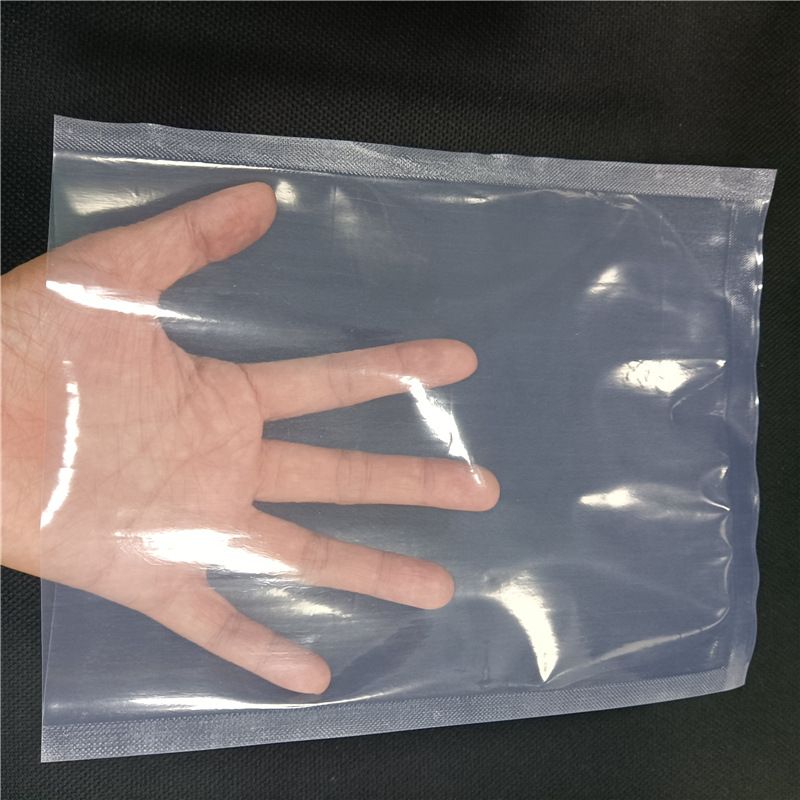

Plastic Nylon Vacuum Pouch is made of nylon and polyethylene double layer. It is transparent on both sides, which can show the product in a more three-dimensional image. It has a good transparent effect, but it can only be boiled. At the same time, nylon has good puncture resistance, soft texture, strong tensile strength, suitable for food packaging such as poultry chicken, duck, goose and other cooked food, or metal bearing product packaging.

1.Plastic Nylon Vacuum Pouch high barrier: has good puncture resistance, ideal vacuum effect, and high cost performance.

2.Plastic Nylon Vacuum Pouch have strong functions: clean, harmless, environmentally friendly and safe, oil-resistant, moisture-resistant, resistant to high-temperature cooking at 90 degrees Celsius, resistant to low-temperature freezing, and can preserve quality, freshness and odor. They can be used for vacuum packaging, aseptic packaging, and inflatable packaging.

3.Plastic Nylon Vacuum Pouch are low-cost: transparent and beautiful, the vacuum-packed items are dynamically visible and easy to identify. Compared with glass packaging, aluminum foil packaging and other plastic packaging, co-extruded film has a greater cost advantage in achieving the same barrier effect.

4.Plastic Nylon Vacuum Pouch have a wide range of applications: Vacuum packaging bags are suitable for industries that require vacuum packaging, such as textiles, food, electronics, hardware, and chemicals.

5.High strength: The co-extruded film has the characteristic of stretching during the processing. The strength of the plastic can be increased accordingly after stretching. Nylon, polyethylene and other plastic materials can also be added in the middle to make it have a composite strength that exceeds that of ordinary plastic packaging bags. There is no delamination phenomenon, good softness and excellent heat sealing performance.